产品概述:

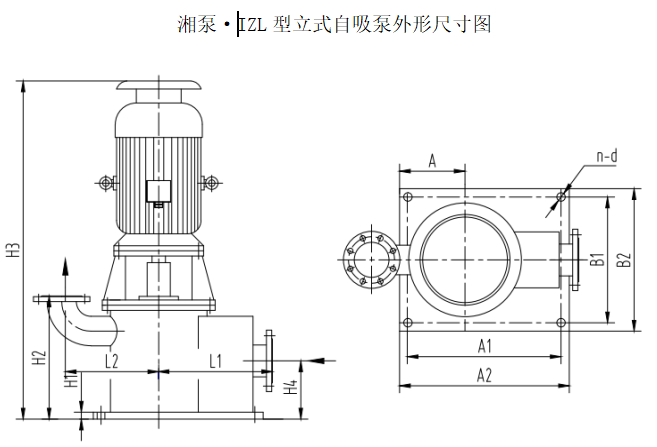

IZL型立式自吸泵概述

IZL型无泄漏立式自吸离心泵,是填补国内空白的首创产品,可输送清水、海水及含较小颗粒(不含纤维状物质)的污水和工业废水,也可用于油料或各种腐蚀性介质,被输送介质温度不高于80℃,

广泛应用于石油、化工、冶金、电力、造纸、环保、污水处理等行业。

IZL型立式自吸泵性能范围(设计点):

转速:980~2950r/min

流量:11.2~1200m³/h

扬程:10~80m

IZL型立式自吸离心泵优点

1.立式安装,占地面积少;

2.启动时只需首次灌注液体;

3.自吸时间短;

4.特别适合需要频繁启动的工况。

5.具有无泄漏,运行可靠,免维护的特点。

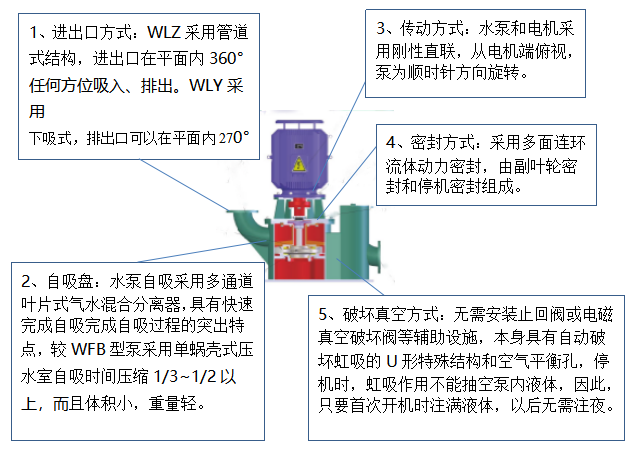

IZL型无泄漏立式自吸泵结构特点:

1、进出口方式:

IZL型泵采用管道式结构,进、出口可在平面360°任何方位吸入、排出。

2、自吸盘:

水泵自吸采用“多通道叶片式气水混合分离器”,具有快速完成自吸过程的突出特点,较WFB型自吸泵采用单蜗壳式压水室自吸时间缩短1/3~1/2以上,而且泵体积小,重量轻。

3、传动方式:

联接方式为水泵和电机刚性直联。从电机端俯视,泵为顺时针方向旋转。

4、密封方式

采用多面连环流体动力密封,由副叶轮密封和停机密封组成。

WFB型流体动力密封未设专用停机密封,不适用于频繁启动场合。

5、破坏真空方式:

水泵进口无需像WFB泵那样带止回阀或电磁真空破坏阀等辅助设备,本身具有自动破坏虹吸的U型管特殊结构和空气平衡孔,停机时,虹吸作用不能抽空泵内储液,因此,只要首次运行时注满液体,以后运行无需加液,真正实现一次注液,终身受用。

IZL型无泄漏立式自吸离心泵型号说明

50IZL11.2-10FⅡ-L

50 —— 进、出口直径50mm

IZL —— 无泄漏立式自吸泵

11.2 —— 设计点流量11.2m³/h

10 —— 设计点扬程10m

F —— 采用副叶轮密封

Ⅱ—— 材料类别Ⅱ类(Ⅰ类不标注)

L —— 液下深度mm

IZL型立式自吸泵零件材料表

零件名称 输送介质 | Ⅰ | Ⅱ | Ⅲ | Ⅳ |

清水 | 污水 | 海水或腐蚀性介质 | ||

泵 体 | Q235-A | Q235-A | 1Cr18Ni9Ti | 0Cr17Ni12Mo2 |

泵盖 | HT250 | HT250 | 1Cr18Ni9Ti | 0Cr17Ni12Mo2 |

叶 轮 | HT250 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 0Cr17Ni12Mo2 |

自吸盘 | HT250 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 0Cr17Ni12Mo2 |

泵 轴 | 45 | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

密封环 | HT250 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 0Cr17Ni12Mo2 |

副叶轮 | HT250 | HT250 | 1Cr18Ni9Ti | 0Cr17Ni12Mo2 |

连接管 | Q235-A | Q235-A | 1Cr18Ni9Ti | 0Cr17Ni12Mo2 |

电机座 | Q235-A | Q235-A | Q235-A | Q235-A |

注:材料可根据用户要求选配。